“Mike, what’s this?” I asked.

“Oh, that’s the spare tire holder for the 100 series Land Cruiser.” Mike answered.

“What about this?” I continued.

“That’s a swing arm for a 200 series ladder.” He answered.

For me, I couldn’t determine or decipher what I was seeing right in front of me. Mike, on the other hand, is a craftsman and fabricator of metal. He transforms metal into works of art. “Art” that is found on 80, 100, and 200 Series Land Cruisers and makes the vehicles more functional and overland capable.

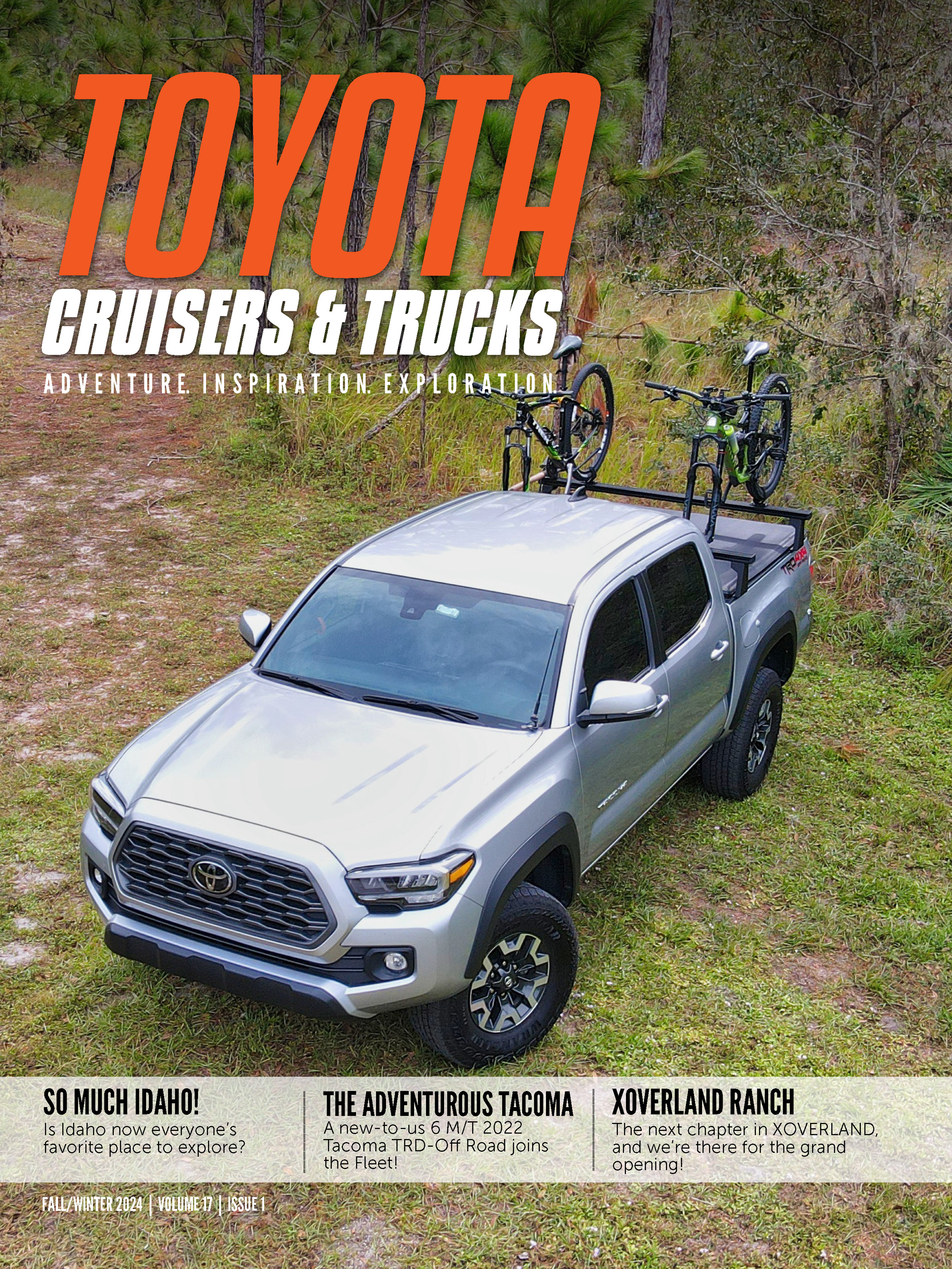

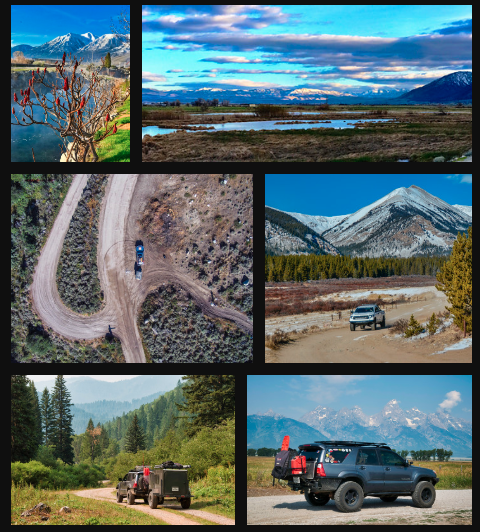

In late Fall 2017, I purchased a used Land Cruiser 200 Series with the goal of building the vehicle to make it overland ready to travel in and around the Intermountain West. I frequently travel the canyon country of Utah and the mountain roads of Idaho, Colorado, and Wyoming. My recent 100 Series Land Cruiser did an admirable job of making travel to remote places comfortable and reliable and I want to replicate and enhance that experience with the 200 Series.

Eight years ago, Mike built my 100 Series rear bumper which still looked new and held up exceptionally well after years of overlanding abuse. So it was natural for me to work with Mike again. There were a few things that I had learned in terms of what I wanted and didn’t want for this new bumper. I wanted dual swing outs: one for carrying extra water and gas and the other for a tire carrier. I also wanted a camp table that deploys quickly. After discussing my ideas, he began the design and fabrication process.

Mike custom builds products to his customers’ wants and needs from his shop, located on the outskirts of Fort Collins, Colorado in the small town of Windsor. The unassuming shop houses all the tools and equipment Mike needs to fabricate solid, functional products for Toyota Land Cruisers. Mike’s love of Land Cruisers began as a child. His first model was the classic FJ40. A former carpenter, Mike designed and constructed overland products for fun and then realized there was a market for his art. The housing crash of 2007 and 2008 “forced” Mike to determine if designing and building metal outfitting products would be a viable business to pursue. All owners look for top-notch quality parts for their Land Cruisers, so it didn’t take long for people to recognize solid, high-quality work. Mike succeeded, and 10 years later, Bump It Offroad is stronger than ever.

The new 200 Series Land Cruiser model was introduced in the United States in 2008. It came with a larger, more powerful engine and many other updates such as electronics, a cooler box, six-speed transmission, crawl mode, and hydraulic suspension. The 200 Series is better than the previous 100 in almost every way. However, once the 200 Series ventures off pavement, its limitations become obvious. I wanted to address departure angles in particular: the rear, plastic bumper hangs low— just asking to be banged, scratched, and ripped. Along with a custom high-clearance bumper, I desired to have swing outs that would carry a spare tire, extra water, and a camp table.

“Mike, do you think you can make this happen?” I asked. “I believe so,” Mike replied. “Let me send you some pictures of some ideas. Let me know your thoughts.”

The other great aspect to working with Mike and Bump It Offroad is that the powder coater he uses is right next door to his shop. Coating Specialties completes all of Mike’s powder coating.

“Those guys do awesome work, so I thought we could work together on products.” Mike said. If an issue arises, he can simply walk next door and address it immediately. On my previous Land Cruiser 100 Series bumper, the powder coating held up exceptionally well. Obviously, Mike can design and build the products, but what makes them look finished is the powder coat.

I received an email showcasing some of the things he had in mind for the rear bumper. Mike owns a 200 Series and was able to show me the rear bumper he created for his personal vehicle and informed me what worked and what didn’t. Having owned many different Land Cruiser models, Mike can share his personal knowledge of various vehicles and workable solutions for products.

My drive across Interstate 80 from Utah toward Windors, CO was uneventful. My stock Land Cruiser purred down the road on they way to Mike’s shop. The 200 Series is incredibly comfortable to drive, and driver fatigue is pretty much nonexistent. The following morning, I arrived at his shop ready to see what Mike had designed and fabricated. We immediately got to work removing the rear stock bumper.

Things progressed well; and before long, Mike asked, “Lunch?” We drove into downtown Windsor to find a local lunch spot. We talked Land Cruisers, travels, and canyoneering in Utah. Mike talked about his involvement in the “100s in the Hills,”“Cruise Moab,” and the “Cruiser Classic in South Dakota.” Mike explained: “I am super busy but take pride in my work. I want to make sure customers are happy with their purchase. Sponsoring and attending events where I get to interact with happy customers is awesome.” Mike informed me. Finishing lunch and conversation, we traveled back to his shop.

Related Articles

“What’s this?” I asked and pointed to something on his table. “That’s your ladder and water/gas carrier.” Mike explained. The ladder looked clean, well-made, professional, and functional.

“Outstanding!” I shouted back. My excitement was hard to hide. The pieces were there; now it was time to create the work of “art.” I helped Mike lift the bumper onto the Land Cruiser’s rear cross member. We tightened a few bolts and stepped back to look it over.The bumper transformed the Land Cruiser from mall cruiser to an overlanding vehicle.

After attaching the main bumper, Mike installed the swing arms. The driver’s side swing arm had a place to store two water/gas cans, a ladder to access the roof, and small camp table attached to it. Mike pointed out that the slots in the rungs of the ladder that could take a bolt head, so I could attach a bike rack or something else. The careful design and concept of the finished product was evident. The second swing arm carried the spare tire, high-lift jack, and water/gas container. Both arms incorporated affixed gas struts, allowing them to open and close easily. Mike wired some taillights into the bumper for extra safety since the spare tire was somewhat blocking the passenger rear taillight. Mike’s attention to the design and details of his finished products was on full display. Now, it was my turn to enjoy the “fruits of Mike’s labor.” I closed the swing arm and shook Mike’s hand.

“Thank you,” I said graciously.

Granted, this was the first step in the build process, and I had a long ways to go to complete the truck. However, Mike’s rear bumper was an excellent start! We discussed a few places to canyoneer in southern Utah later that spring. Unfortunately, Interstate 80 called, and I had to begin to travel back to Utah. To stay awake, I envisioned the truck completely built.

April, 2018; Grand Staircase Escalante National Monument

My family and I are in the wilds of southern Utah, ready to enjoy spring. Louise places some breakfast items on the small table attached to the driver’s side swing arm while I fill the JetBoil with water. The glowing morning sun warms our campsite deep in canyon country. I marvel at how the bumper just functioned and worked as intended.

Overlanding through the wilds of the US in search of experiences and adventures is a blast—especially, when all the gear works and functions, as it should. What does your vehicle need? What products would allow you safer and more functional travel while overlanding? I can’t answer those questions for you, but I know who could—The Land Cruiser Craftsman.

[flickr set=72157700696540215]

To get your copy of the

Spring 2018 Issue:

Follow us on Facebook, Twitter, and Instagram to get up-to-date industry news, events, and of course, amazing adventures, stories, and photos!